Blutec 30 años de experiencia en el mercado

-

Teléfono

(+52) 222 88 88 624

-

Horario de oficina

Lunes - Viernes 08:00 to 18:00

-

Escríbenos

info@blutec.com.mx

Agencia líder en tecnología

textil en todo México.

#TechnologyIsBlue.

Últimas

tecnologías

Representamos a las firmas más exclusivas a nivel mundial en la fabricación de maquinaria y proceso para la industria textil.

Asesoramiento

textil

Estamos capacitados para brindarte información personalizada sobre el producto necesario y óptimo para tu compañía.

Mantenimiento

experto textil

Brindamos asistencia técnica con el personal capacitado, acompañado por el asesoramiento e intervención de nuestras compañías representadas.

Repuestos

textiles

Tenemos un área especializada y ligada a nuestras representadaspara brindar rápidez y efectividad en las refacciones de las máquinas de nuestros clientes.

BIENVENIDOS

Son 30

años de

experiencia.

La principal fortaleza de Blutec es la experiencia; a lo largo de 30 años hemos logrado construir relaciones duraderas con nuestros clientes gracias a nuestra filosofía de servicio que se basa en el seguimiento puntual de las necesidades de nuestros clientes.

Uno de nuestros principales retos es cumplir en tiempo y en forma con las solicitudes de nuestros clientes aún cuando los insumos son adquiridos alrededor de todo el mundo. A todos y cada uno de nuestros clientes, muchas gracias por su confianza.

LA EXPERIENCIA NOS RESPALDA

Servicios de BLUTEC

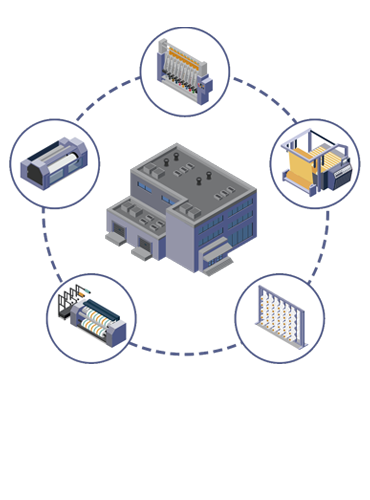

Consulta nuestras representadas