WE CONTINUE TO GROW

The history of Scholze Germany begins in 1921 in Zittau, Saxony, with the foundation of the company Reinhold Scholze, which produced accessory parts for important weaving looms. Over time, the spectrum of service of the growing, proactive company Scholze changed, and in the 1950’s, the company initiated the serial production of loom beams.

Today, Scholze Germany at the Frankenberg location in Hesse represents an internationally-renowned manufacturer of weaving machine accessories, focussing on back and loom beams as well as bobbins, canisters, cloth beams, tubes and flanges. The consistently high quality of the products is assured through stringent inspections and the professional training and further training of the employees. We use matured production procedures for fast, reliable and economically-viable production.

Since 2009, we have belonged to the Neuenhauser Group of Companies, which connects us with other experienced and high-performance companies. We value the possibilities for exchange and further development which have characterised the company since its beginnings.

QUALITY WITH TRADITION

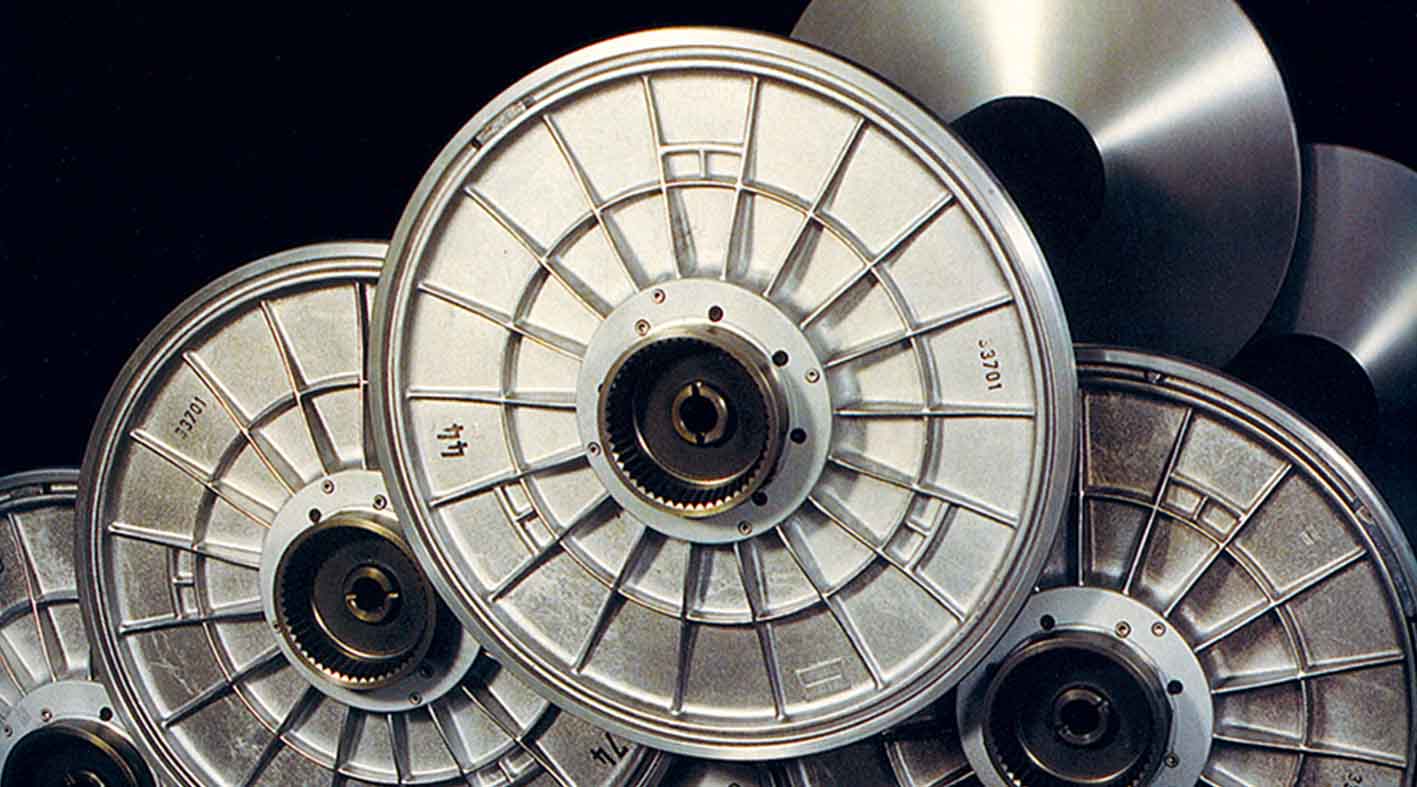

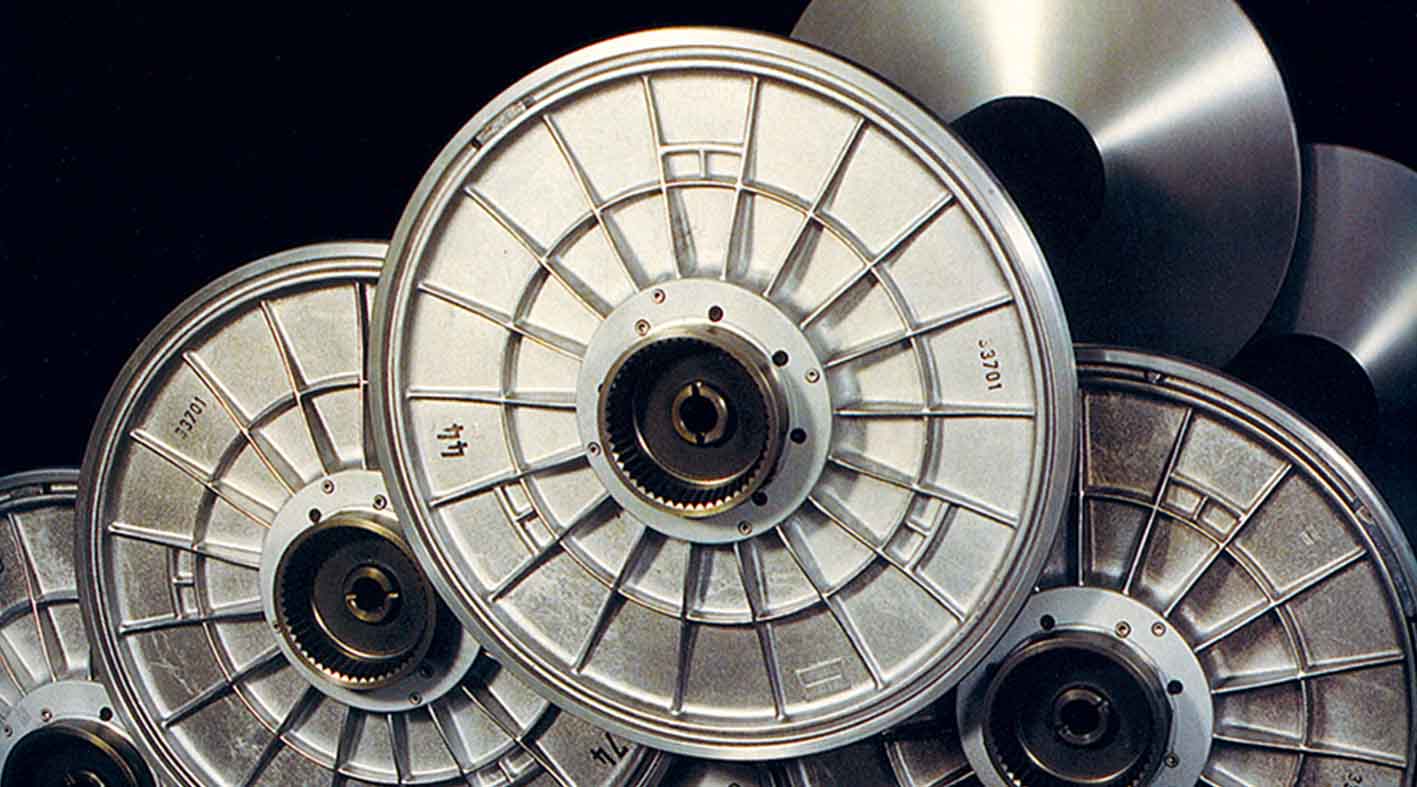

The comprehensive experience which we possess in the field of textile technology is reflected in every single flange which leaves our Production. Flanges made from aluminium were cast into solid shapes for the first time at Scholze in 1936. Today, we utilise the efficient permanent mould casting process to produce accurate flanges with optimised price-performance ratios. We keep our delivery times short for the benefit of our customers.

Scholze Germany offers the full range of flanges to cater for all cases arising in practical application. This high level of flexibility and variability is facilitated through a gapless system of fully-ribbed flanges, smooth flanges and universal-use, double-walled flanges.

Customised flanges

Gapless coverage of all quality classes

For different requirements

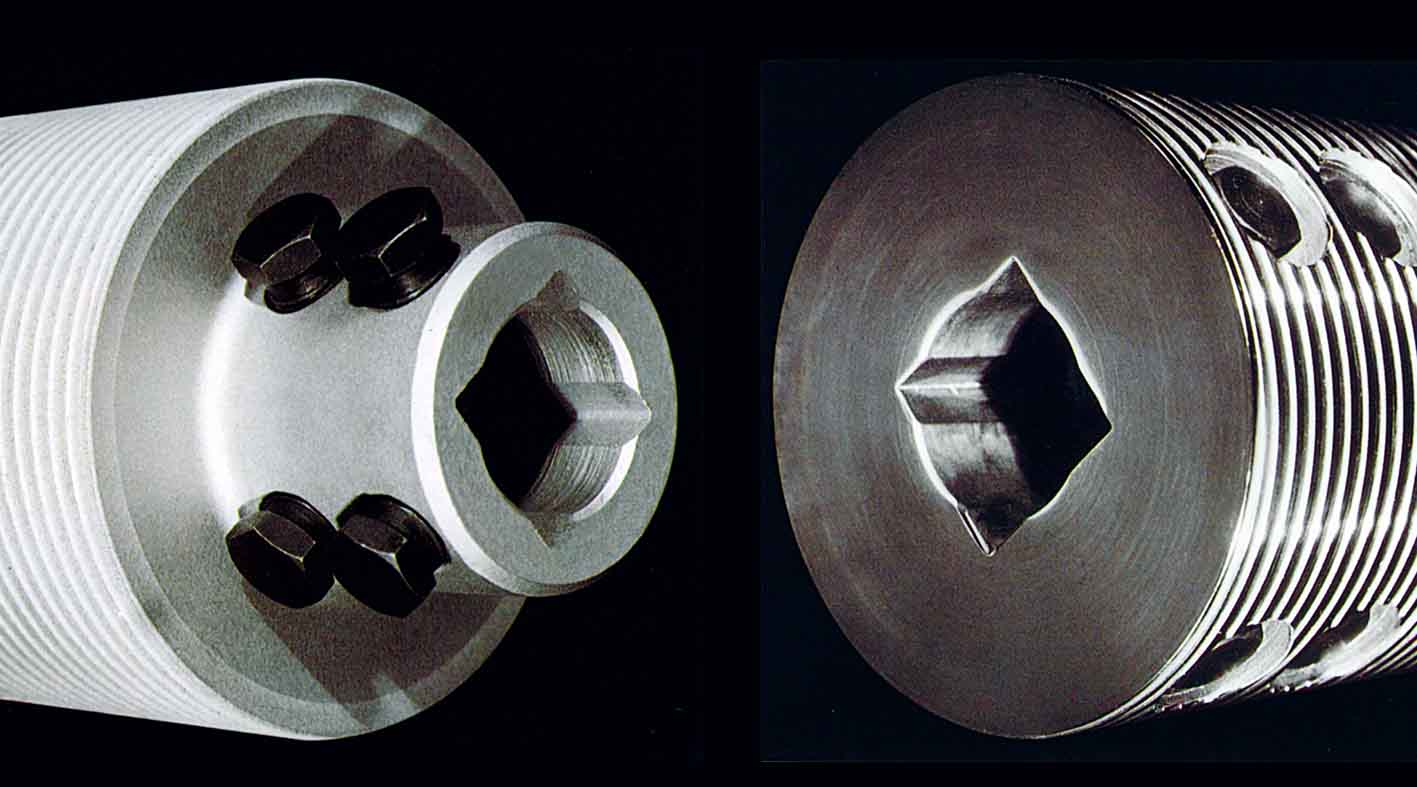

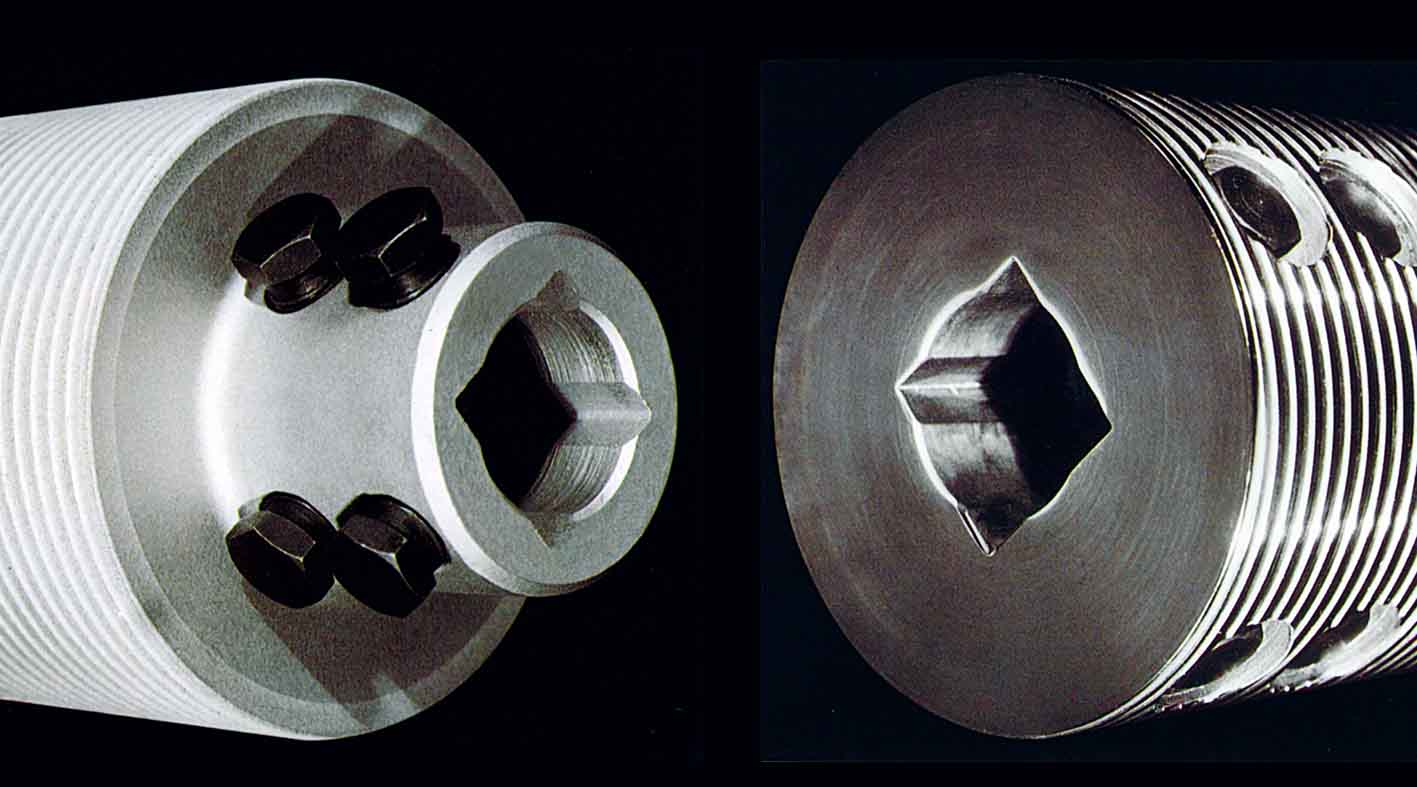

The simple ribbed flanges as an inexpensive and simultaneously reliable alternative with tried and tested Scholze quality are used when processing yarns made from natural fibres, with the exception of silk. They are particularly suitable for fixed weaving programs with identically-dimensioned beam units which are rarely or never changed. The double-walled flanges are designed for low to maximum pressure loads, as they are able to avoid thread clamping through their elasticity. At the same time, we offer the possibility of individual design and production for very specific requirements and develop solutions which could not be a more perfect fit.

- Perfect edge formation

- Easy handling

- Surface of flange interiors in natural aluminium is suitable for fibres

- Locking system comprising a counter ring, radial lock and axial lock

If you wish to find out more about the Neuenhauser Group, please click here:

www.neuenhauser.com