KARL MAYER’s warp sampling machine has been successful in gaining a foothold on the Portuguese market

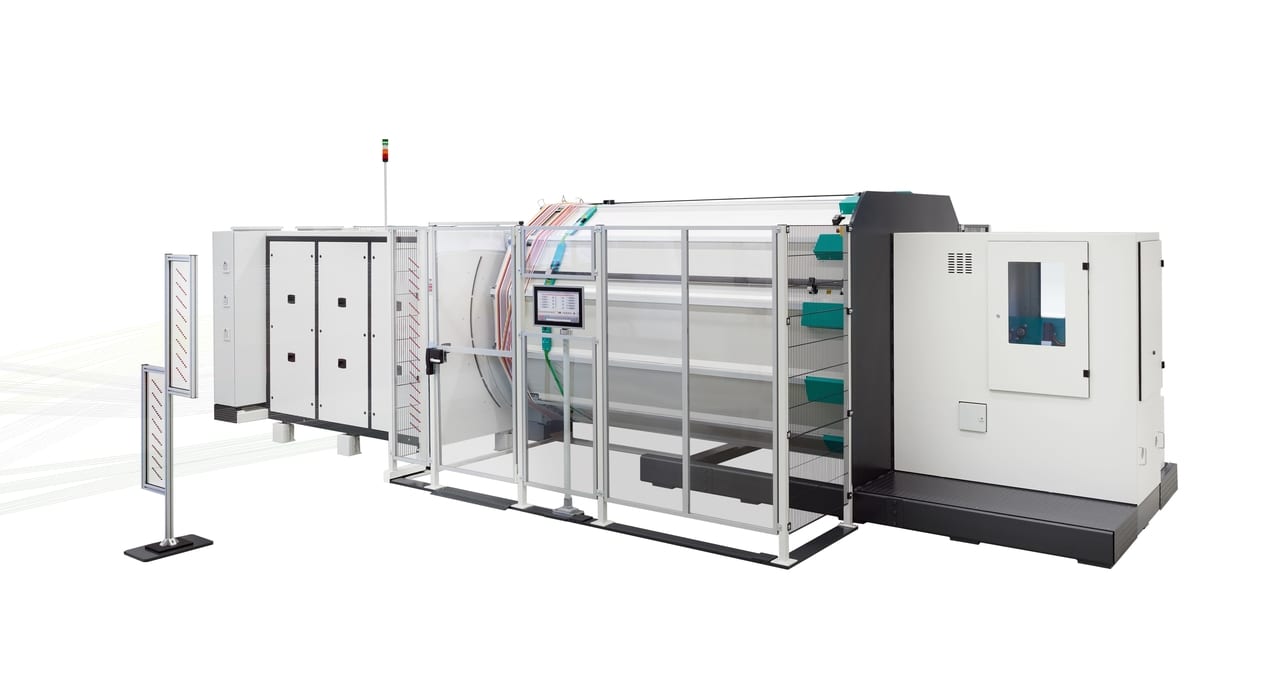

No matter if exclusive shirtings and suitings with multicoloured patterns and in small production runs or high-quality furnishing textiles and upholstery articles with striking designs in large fabric widths – KARL MAYER’s MULTI-MATIC® is always much in demand if it comes to flexibility, quality and efficiency. Compared to present conventional counterparts, this allround machine enables to increase the production of sample warps fourfold and that of plain warps even eightfold. The system provides an automatic colour change: 128 yarn guide fingers are individually controlled and precisely guided without any loss of speed. The positioning accuracy of the yarn selection is 0.05 mm, with an acceleration of 200 m/s². The results are premium-quality products. The beams having lengths of up to 1,500 m are characterized by uniform lap build-up, constant yarn tensions and precise material laying.

Flexibility and rapid amortization – the recipe for success for „made in Europe“

With this performance it goes without saying that the MULTI-MATIC® pays off even after a short period of time. „In case of an optimum economic use, the payback time is less than four years“, this is the experience of Dieter Gager, Vice President Sales and Marketing of KARL MAYER’s Business Unit Warp Preparation.

So far, the most feedback has been coming from the Italian market. The land of fashion has a lot of manufacturers who rely on collections with diverse patterns, high level of quality and short order cycles. The companies need premium warps for patterning and production. Nevertheless, during the last five years Dieter Gager and his sales team have been registering a growing interest in this machine type also from another country: namely from the fabric manufacturers in Portugal. „In the recent past we sold six MULTI-MATIC® machines to Portugal. A seventh machine is currently under negotiation“, explains Dieter Gager. Main reasons for the favourable investment climate in Portugal are the extremely fast style changes of the leading brand suppliers. Fashion companies like H&M and ZARA provide new collections twice a month, so that the supply chain is put under significant time pressure. The proximity to the sales and logistics centers becomes an important success factor, so that Europe is again an important production location – and Paulo de Oliveira can also benefit from this development, for example.

Paulo de Oliveira relies on the MULTI-MATIC®

This family-run traditional company was founded in 1936 by José Paulo de Oliveira as a weaving mill and has its registered office in Covilhã. In the course of its history, the enterprise has developed to a fully integrated textile company with an export share of more than 90 %. Today, the vertical production capacities include a spinning plant, a weaving mill and a finishing department including a dyeing section. On an area of 40,000 m² the Paulo de Oliveira company produces 10 million square meters of fabric per year (worsted fabrics), being one of the 3 biggest wool producers in Europe. As far as the machinery and equipment technology is concerned, this company fully relies on state-of-the-art models for all its production areas. Paulo de Oliveira has always understood that the company’s equipment with the latest available technology is the prerequisite to produce high-quality articles at a competitive price, and within reasonable delivery times.

The highest investments during the last few years are focused on warp preparation as well as weaving. Main objective of the spending was to make the production process even more flexible: It should be ensured to manufacture more demanding articles in ever shorter series and with ever shorter lead times and with very high quality.

So, the first MULTI-MATIC® machine was ordered in 2013 and in 2018 there followed another model which was installed by mid of October. The Portuguese company uses KARL MAYER’s warp sampling machine to produce premium beams for high-quality worsted suits. In the words of Mr. Dr. Luís Oliveira, today’s Managing Director and one of the sons of the company Founder: “The machine is fast, flexible and helps us to save energy and yarn.“